Did you know that a well-maintained grandfather clock can be a treasured family heirloom for generations? These majestic timepieces not only keep precise time but also add a touch of elegance to any room. However, like any mechanical device, they require occasional clock repair to function smoothly.

The good news is that many common issues with mechanical clocks can be resolved without professional help, saving you time and money. With a little patience and the right guidance, you can keep your grandfather clock ticking away accurately.

This guide will walk you through 10 practical clock repair hacks designed specifically for beginners. You’ll learn how to adjust the pendulum, manage weights, and apply oiling techniques to keep your clock running smoothly.

Key Takeaways

- Learn how to troubleshoot common issues with your grandfather clock

- Discover simple repair techniques to keep your clock accurate

- Understand the importance of regular maintenance for your mechanical clock

- Find out how to adjust the pendulum and manage weights

- Master oiling techniques to keep your clock running smoothly

- Extend the life of your grandfather clock with proper care

Understanding Your Grandfather Clock

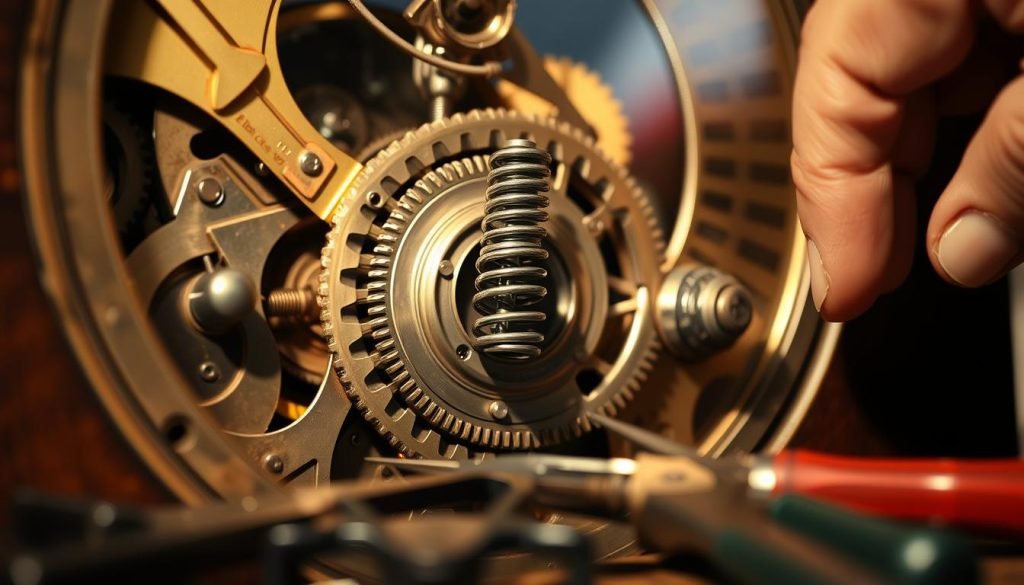

To effectively repair and maintain your grandfather clock, it’s crucial to understand its fundamental components and how they work together. A grandfather clock is a complex mechanical device that requires a basic understanding of its mechanics to diagnose and fix issues.

The Basic Mechanics of a Grandfather Clock

The mechanics of a grandfather clock are driven by a weight-powered escapement mechanism. The weights pull on the gears, causing the hands to move and the chimes to play. Over time, dust, oil buildup, and misalignment can affect the movement’s performance. The movement is the “brain” of the clock, containing all the gears and mechanisms that control timekeeping and striking.

Common Parts and Their Functions

Key components of a grandfather clock include the case, dial, hands, weights, pendulum, movement, and chime rods. The clock face, or dial, displays the time, and the minute and hour hands connect to the movement through the center arbor. The pendulum plays a crucial role in timekeeping accuracy, with its bob’s weight affecting the clock’s rhythm. The weights are connected to the movement via pulleys and cables or chains, transferring power to keep the clock running. Understanding these parts and their functions is essential for effective maintenance and repair.

Essential Tools for DIY Grandfather Clock Repair

Before diving into grandfather clock repair, it’s essential to gather the necessary tools. Having the right equipment not only makes the process smoother but also ensures that you can complete repairs effectively and safely.

Basic Tools Every Clock Owner Should Have

Every clock owner should have a basic toolkit that includes tweezers and pegwood. Tweezers help remove lint and debris from hard-to-reach places inside the clock movement. Pegwood is used for cleaning pivot holes and removing old oil without scratching brass plates. These tools are fundamental for basic maintenance tasks.

Specialized Tools for More Complex Repairs

For more complex repairs, you may need specialized tools such as movement holders, bushing tools, mainspring winders, and staking sets. A let-down key is crucial for safely releasing mainspring tension before working on the movement. Specialized cleaning solutions designed for clock movements are also essential, as they won’t damage brass or steel components. Proper lighting and magnification are vital when working on intricate clock mechanisms. While these tools aren’t necessary for basic maintenance, they become essential for more complex repairs. Beginners might consider renting or borrowing these specialized tools before investing in them for occasional use.

Hack #1: Properly Moving Your Grandfather Clock

The process of moving a grandfather clock involves more than just lifting it; it requires a thoughtful approach to prevent damage. One of the most common issues encountered when relocating a grandfather clock is the tangling of weight lines during transport, which can prevent the clock from operating properly.

Securing the Pendulum and Weights

Before moving your clock, it’s crucial to secure the pendulum and weights. If your antique longcase clock refuses to run after moving and you’ve carefully unhooked the weights first, it’s likely that there was still line on the barrel. When the weight was removed, the line relaxed, allowing the coils to become entangled. To avoid this, let the clock run right down on both sides so that there’s no line left on the barrel before removing the weight.

To properly secure the lines: Use tape or twist ties to keep them from unwinding. Wrap the lines carefully around the movement to prevent tangling. Check for proper line alignment on the pulleys before reinstalling the weights.

Preventing Line Tangling During Transport

If the clock must be moved before running down, secure the lines with tape or twist ties. Here’s a step-by-step guide:

| Step | Description |

|---|---|

| 1 | Carefully wrap the lines around the movement. |

| 2 | Secure the lines with tape or twist ties. |

| 3 | Check for proper line alignment on the pulleys. |

It’s also important to be aware of the difficulty of untangling lines once they’ve become crossed or knotted inside the case. If prevention methods weren’t used, troubleshooting tips include removing the weight again to untangle the coil.

By following these steps, you can ensure that your grandfather clock is moved safely and remains in good working condition.

Hack #2: Fixing a Clock That’s Out of Beat

When a grandfather clock’s tick-tock is uneven, it’s a clear indication that something is amiss, and adjustments are needed to restore its rhythmic heartbeat. An out-of-beat clock not only sounds irregular but can also be a sign of a deeper mechanical issue that needs to be addressed.

Identifying an Uneven Tick-Tock

The first step in fixing a clock that’s out of beat is to identify the issue. Listen carefully to the tick-tock sound. If it’s uneven, one tick might be louder or occur slightly before the other. This unevenness can be due to the clock not being perfectly level or an issue with the crutch that connects the escapement to the pendulum.

A simple, temporary solution used to be to place pennies under one side of the clock’s base until the tick-tock was even. However, the permanent fix depends on the type of clock you have.

Adjusting the Crutch for Perfect Timing

The crutch plays a crucial role in the clock’s timing, acting as the connection between the escapement and the pendulum. Adjusting it can affect the beat. To achieve an even tick-tock, you may need to adjust the crutch on the movement or use shims/adjustable feet to level the clock case.

| Adjustment Method | Description | Effect on Clock |

|---|---|---|

| Leveling the Clock Case | Using shims or adjustable feet | Corrects minor beat issues |

| Bending the Crutch | Carefully adjusting the crutch on the movement | More permanent adjustment for beat correction |

It’s crucial to make small adjustments and test the beat after each change to avoid over-correction. Some grandfather clocks have a beat adjustment screw that simplifies this process. Patience is key, as forcing the crutch can damage the delicate escapement mechanism.

Hack #3: Top 10 Grandfather Clock Repair Tips for Beginners

Maintaining your grandfather clock requires a blend of regular upkeep and knowing when to call in a professional. To keep it running smoothly, you need to understand the basics of clock maintenance and when to seek expert help.

Diagnosing Common Issues Before Calling a Professional

Before calling a professional, it’s crucial to diagnose common issues with your grandfather clock. Start by checking the power source; ensure it’s wound properly and that the weights are correctly positioned. Listen to the tick-tock sound; an uneven beat could indicate a problem with the pendulum or the movement. Check for any visible signs of wear or damage on the clock’s face, hands, and mechanism.

Some common issues include the clock stopping or running slow, chimes not sounding correctly, or the clock striking the wrong hour. For instance, if your clock has stopped, check if it’s due to a lack of winding or if the pendulum is out of swing. Understanding these basic diagnostics can save you time and money by avoiding unnecessary service calls.

Simple Maintenance Routines to Prevent Problems

Establishing a regular maintenance routine is key to preventing problems with your grandfather clock. This includes weekly winding to keep the mechanism powered, monthly cleaning of the case and dial to prevent dust buildup, and periodic professional servicing to ensure the clock’s intricate parts are well-maintained.

Consistent winding on the same day each week helps maintain optimal power in the movement. When cleaning, use a soft cloth to dust the case, dial, and accessible parts of the movement gently. For the glass door and brass components, use appropriate cleaning solutions to avoid damage. Maintaining proper humidity levels is also crucial to prevent wood case warping and metal corrosion.

| Maintenance Task | Frequency | Benefit |

|---|---|---|

| Winding | Weekly | Maintains optimal power |

| Case and Dial Cleaning | Monthly | Prevents dust buildup |

| Professional Servicing | Every 10 years or as needed | Ensures intricate parts are well-maintained |

By following these simple maintenance routines, you can significantly extend the life of your grandfather clock and ensure it continues to keep accurate time. Remember, preventative maintenance is more cost-effective than repairing damage from neglect.

Hack #4: Regulating a Clock That Runs Fast or Slow

Adjusting a grandfather clock to keep perfect time involves understanding the role of its pendulum and making precise adjustments. To achieve accurate timekeeping, you need to regulate the clock’s mechanism so that it keeps pace with the standard time.

Understanding the Pendulum’s Role in Timekeeping

The pendulum plays a crucial role in the timekeeping of a grandfather clock. Its swing regulates the clock’s movement, ensuring that it ticks at a consistent rate. The length of the pendulum and the position of its bob significantly affect the clock’s accuracy. If the clock is running fast or slow, it’s likely because the pendulum bob is not in the optimal “sweet spot” where it causes the pendulum to swing once per second.

Using the Dividing Halves Method for Precise Regulation

To regulate your clock, you can use the dividing halves method, a systematic approach to adjusting the pendulum’s length. First, compare your clock’s timekeeping to an accurate reference timepiece over a set period, such as five minutes. If your clock is running fast, turn the nut at the bottom of the pendulum rod downwards by ten full rotations. If it’s running slow, turn it upwards by ten rotations. Continue this process, adjusting the pendulum and checking the timekeeping against your reference until the clock’s error reverses direction. Once you’ve passed the “sweet spot,” you can start making smaller adjustments, halving the amount each time, until you achieve precise regulation.

| Adjustment | Direction | Effect on Clock |

|---|---|---|

| Lowering Bob | Downwards | Runs Slower |

| Raising Bob | Upwards | Runs Faster |

Regulating a grandfather clock requires patience, as achieving perfect timekeeping may take several days of observation and adjustment. Additionally, environmental factors like temperature changes may necessitate seasonal adjustments to maintain accuracy.

Hack #5: Proper Oiling Techniques

Oiling your grandfather clock is a delicate process that requires precision and the right techniques. Proper oiling is essential for the longevity and accuracy of your clock. It involves understanding which parts need lubrication and how to apply the oil correctly.

Choosing the Right Oil for Different Parts

Not all clock parts require the same type of oil. For instance, the escapement pallets need a specific type of lubricant that won’t attract dust or compromise the clock’s accuracy. It’s also crucial to avoid using WD40, as it’s a water repellent, not a lubricant, and can damage brass components. When selecting oil, consider the material of the parts you’re lubricating.

Key Considerations: Choose oil suitable for clock mechanisms, avoid WD40, and consider the material of the parts.

Where and How Much to Oil

The pivot points where arbors meet the plates are critical areas that require oiling. Use fine oilers or toothpicks to apply tiny drops precisely where needed. Remember, the “less is more” principle applies here; excess oil can attract dust and cause more problems. Gear teeth generally should not be oiled as this can affect their meshing and collect debris.

Application Tips: Oil pivot points carefully, avoid oiling gear teeth, and use the right amount to prevent dust accumulation.

Hack #6: Fixing Striking and Chiming Issues

The striking and chiming features of grandfather clocks can sometimes be problematic, necessitating repair. When your clock’s striking or chiming mechanism malfunctions, it can be due to a variety of reasons, ranging from simple issues like insufficient winding to more complex problems such as misaligned strike levers or worn-out hammers.

Resynchronizing Out-of-Sync Strikes

If your clock has stopped between 12 and 1 o’clock and you feel some resistance when trying to move the minute hand forward, it’s likely that the strike train has run down and lost power before completing its strike sequence. To resolve this, try turning the minute hand back two or three minutes, then wind the strike side (usually the one on the left). Allow the strike to complete its sequence, and you should find that the minute hand is now free to turn forwards again to set the correct time.

Troubleshooting Silent Chimes

Silent or weak chimes can be caused by several factors, including worn hammers, misaligned strike levers, or insufficient power. To troubleshoot, first check if the strike train is wound properly, as many owners focus only on the time train. Inspect the hammer alignment with the chime rods or gong and make simple adjustments as needed.

| Issue | Cause | Solution |

|---|---|---|

| Silent Chimes | Worn hammers or misaligned strike levers | Inspect and adjust hammer alignment |

| Out-of-Sync Strikes | Strike train lost power | Wind strike side and resynchronize |

| Clock “locked” in mid-strike | Strike train obstruction | Check for obstructions and release |

To achieve optimal sound quality, adjust the hammer height without damaging the chime rods. If silent chimes persist, it may indicate more serious issues requiring professional attention.

Hack #7: Dealing with Broken or Damaged Mainsprings

Dealing with a damaged mainspring requires careful consideration and the right approach. A mainspring is crucial for the operation of your grandfather clock, providing the power needed to keep it running. When it breaks or gets damaged, it can significantly affect the clock’s performance.

Identifying Mainspring Problems

Identifying issues with the mainspring is the first step towards resolving them. Common signs include the clock stopping or running irregularly. If your clock has stopped and you’ve wound it properly, the mainspring might be broken. Inspecting the spring for visible damage or breaks is essential. You should also check for any signs of wear or corrosion that could indicate a potential problem.

When to DIY and When to Call a Professional

While some mainspring issues can be addressed by experienced hobbyists, many require professional expertise. Working with mainsprings can be dangerous due to the potential for sudden release of tension, leading to injury. Specialized tools and skills are necessary for safe and proper replacement. If you’re unsure, it’s best to consult a professional horologist.

| Issue | DIY Feasibility | Professional Recommendation |

|---|---|---|

| Broken Mainspring | No | Yes, due to safety risks and required expertise |

| Mainspring Wear | Maybe, with experience | Yes, for thorough inspection and service |

| Corrosion | No | Yes, to prevent further damage |

Replacing a mainspring can also be an opportunity to service the movement fully, especially if it hasn’t been overhauled in the past five years. The cost of a new mainspring is typically under £20, but fitting it can cost twice that amount or more, unless it’s a German movement. Modern replacement springs are designed to be safer and more durable.

Hack #8: Correcting Hand Movement Problems

To keep your grandfather clock running accurately, addressing hand movement problems is key. Hand movement issues can lead to inaccurate timekeeping and potentially cause your clock to stop working altogether.

Safely Adjusting Clock Hands

When adjusting clock hands, it’s crucial to do so safely to avoid damaging the delicate components. First, ensure that the clock is stopped before making any adjustments to the hands. To adjust the hands, gently grasp the hand you wish to adjust and carefully move it to the correct position. Be cautious not to apply too much pressure, which could bend or break the hand.

Proper clearance between the hour and minute hands is essential. Check that the hands are not touching each other or the dial. If they are, you may need to adjust their height or bend them slightly to achieve proper clearance.

Fixing Hands That Catch or Bind

Hands that catch or bind can be caused by several factors, including bent hands, loose mounting, or improper clearance between the hands and the dial. To fix this, inspect the hands for any visible bends or misalignments. If a hand is bent, you can carefully straighten it. For loose hands, tighten them on their arbors, taking care not to overtighten, which could damage the mechanism.

It’s also important to check that the hands are not touching the glass or each other at any point during their rotation. Adjusting the hand height can help ensure smooth movement. If binding issues persist, it may indicate a deeper problem with the motion work connecting the minute and hour hands, requiring professional attention.

Hack #9: Basic Cleaning Without Disassembly

Maintaining the beauty and functionality of your grandfather clock involves regular cleaning, which can be achieved without disassembly. This approach ensures that your clock continues to run smoothly and accurately, while also preserving its aesthetic appeal in your home.

Safe Cleaning Methods for Movements

When it comes to cleaning the movement of your clock, it’s crucial to be gentle to avoid causing any damage. While the movement is warm, you can start oiling it. Use just enough oil to lubricate, and no more. Too much oil will not harm the clock immediately, but it can make it really gooped up in years to come when it’s time to clean again. Apply a drop of oil in every spot that rubs together, ensuring that it doesn’t run down the clock plate.

Cleaning the Case and Glass

For the case, use appropriate furniture polishes and soft cloths to clean wooden surfaces without damaging the finish. When cleaning clock glass or plastic crystals, avoid using harsh chemicals or abrasives that can scratch or damage surrounding finishes. For brass components, use methods that remove tarnish without affecting the patina or original finishes. When dealing with intricate carvings or details on ornate cases, gentle brushing or soft cloths can help prevent damage. Additionally, address common case issues like loose moldings, door hinges, or feet by tightening or adjusting them as needed.

It’s also important to use minimal moisture when cleaning wooden cases to prevent warping or finish damage. By following these guidelines, you can keep your grandfather clock‘s case looking its best without compromising its integrity or the clock’s overall functionality.

Hack #10: Troubleshooting a Stopped Clock

Troubleshooting a grandfather clock that’s stopped requires a systematic approach. Understanding the common issues that cause a clock to stop can help you diagnose and potentially fix the problem.

Systematic Approach to Diagnosis

When your clock stops, the first step is to observe the position of the weights. If one weight is consistently level with the weighted bob at the bottom of the pendulum, it might indicate that the pendulum is rubbing against the weight or that the case is experiencing sympathetic vibration.

Quick Fixes for Common Stopping Issues

To address common stopping issues, you can try a few quick fixes. First, ensure the clock is level; if not, use shims or adjustable feet to correct this. Securing the clock case to the wall can prevent sympathetic vibrations, especially on wooden floorboards or carpets.

Check for pendulum obstructions and adjust the clock’s position if necessary. Also, inspect the weight lines for tangles or crossed lines and adjust the pulleys as needed.

As a general rule, if your clock has stopped, it’s essential to methodically check each component to identify the root cause. By doing so, you can often resolve the issue without needing extensive repair help.

Conclusion

Mastering the art of grandfather clock repair is not only cost-effective but also a journey of discovery into the intricate mechanics of these antique marvels. By applying the 10 hacks outlined in this guide, you’ll be able to address many common issues on your own, saving time and money. Regular maintenance is key to preventing more serious problems down the line. Start with simpler repairs to build your confidence, and remember that patience and gentle handling are crucial when working with these delicate timepieces. Share your experiences and tips with the community to further enrich your understanding.